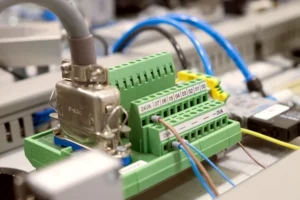

The automotive industry is undergoing a massive transformation with the rapid rise of electric vehicles (EVs), autonomous driving systems, and smart infotainment. At the core of these technological changes lies the need for high-precision connectors.

Connectors are no longer simple mechanical components—they are the lifeline of automotive electronics. From battery management systems (BMS) and inverters to radar sensors and advanced driver-assistance systems (ADAS), every application requires stable, reliable, and safe electrical connections.

One of the key challenges in automotive design is ensuring that connectors can withstand extreme conditions, including vibration, temperature fluctuations, and humidity. A weak or unstable connector could result in communication failure or even system breakdown. Therefore, automotive manufacturers are demanding connectors with:

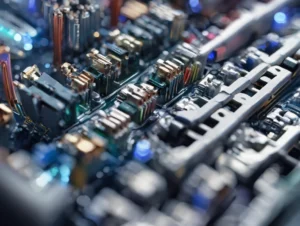

- High vibration resistance to support long-term use in harsh driving environments.

- Superior conductivity for efficient energy transfer in EV battery systems.

- Miniaturization & precision to support compact designs in modern vehicles.

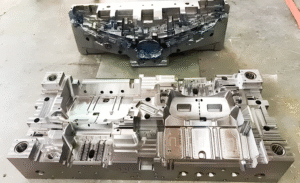

At SmartElecParts, we specialize in developing precision connectors tailored to the automotive sector. Our advanced manufacturing processes—covering precision stamping, injection molding, and automated assembly—ensure consistent quality and performance.

As EV adoption continues to grow worldwide, high-performance connectors will play a critical role in improving safety, extending battery life, and enabling the next generation of smart mobility.