In today’s fast-paced electronics market, manufacturers need suppliers that can deliver high-quality components at scale, with fast lead times. This is where smart manufacturing plays a vital role.

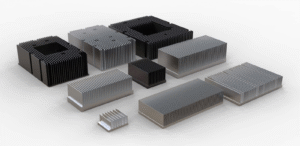

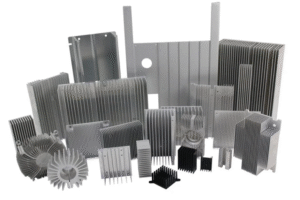

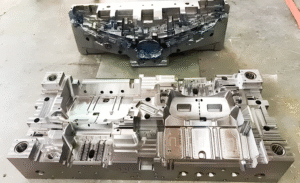

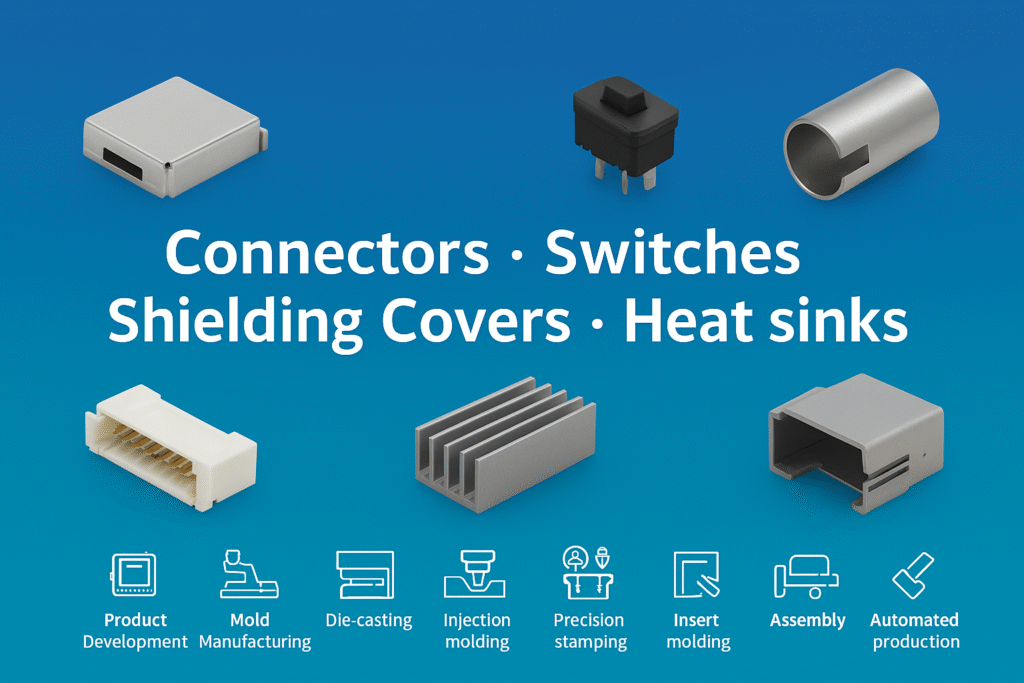

At SmartElecParts, we have invested heavily in automated production lines for precision connectors, switches, shielding cans, and heat sinks. Our production capabilities include:

- High-speed stamping for metal precision parts.

- Injection molding & die-casting for durable component housings.

- Automated assembly to ensure consistent quality and efficiency.

The advantages of automated production are clear:

- Consistency & Precision – Each product meets strict tolerance requirements.

- Scalability – Ability to handle both small-batch prototypes and large-volume orders.

- Shorter Lead Times – Faster turnaround to meet global customer demand.

- Cost Efficiency – Optimized production reduces waste and improves competitiveness.

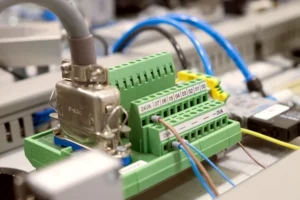

Industries such as consumer electronics, smart home, medical devices, and automotive electronics require increasingly complex components. With automated and flexible production systems, SmartElecParts ensures customers get reliable solutions that keep them ahead of the competition.

As global demand for precision electronic parts continues to grow, smart manufacturing will define the future of the industry—and SmartElecParts is ready to lead the way.